The high power ratings and the abrupt load variations induce thermal stresses on the devices, characterized by high temperature levels and strong temperature changes, leading finally to failures.

Therefore, power cycling test platforms are needed in order to wear-out the power modules in an accelerated manner. By emulating temperature changes similar to those appeared in real applications, failure mechanisms (bond wire lift-off, solder joint fatigue) are triggered in a short period of time. Further on, health monitoring and lifetime prediction models can be applied and quantify the reliability performance of the power modules.

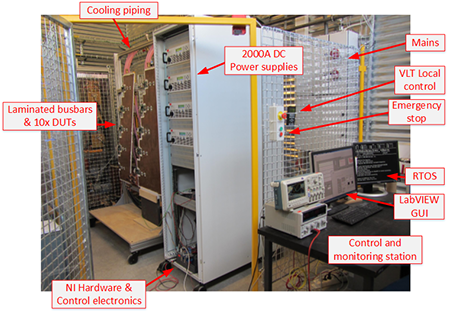

It is an experimental setup, located in the facilities of Energy Technology Department AAU, designed to wear-out high power IGBT modules.

The test setup is partially sponsored by The Obel Family Foundation

Figure 1 Overall view of test setup in the laboratory

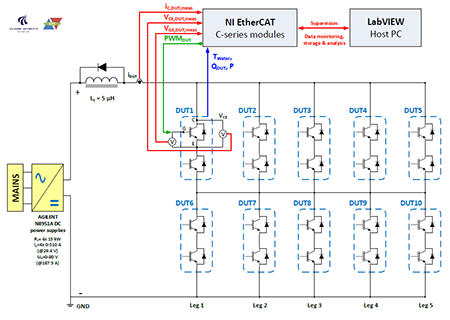

Figure 2 Schematic diagram of the setup

| Type of DUT | PrimePACK™3 modules |

| Max. No. of DUTs | 10 devices |

| DC current, Ic | < 2000A |

| ΔTjunction | <150oC |

| Duty Cycle | ton=2sec , toff=8sec (adjustable) |

| Cooling water temp. | 25 oC - 80 oC |

| Gate Voltages | -10V / 15V |

Table 1: Design Specifications

Objectives of the setup

In general, this setup aims to contribute to the ongoing research activity in the direction of reliable, feasible and cost effective solutions for the wind power industry. Particularly, more reliable and accurate online methods to estimate the junction temperatures inside a power converter are demanded.

In addtion, the conventional lifetime models (e.g Coffin-Manson) have to be validated or modified and imporved. Based on the above considerations, a number of goals have been set for SVEN setup as follows:

- Develop, apply and validate junction temperature estimation methods for the power modules

- Wear-out power modules with different temperature levels and investigate their failures

- Build-up curves of number of cycles-to-failure and apply lifetime estimation models to predict the life expectancy of a specific product